America’s Gate Company wants to make it easy for you to select your cantilever slide gate for your home, business or job site. In this article, we will discuss the different types of cantilever gates and what factors you should consider when choosing the right gate for your project. If you are unsure if a cantilever slide gate is the correct gate for your project, you can view the America’s Gate Company guide to choosing your gate to see a breakdown of all gates we supply.

Cantilever Slide Gates

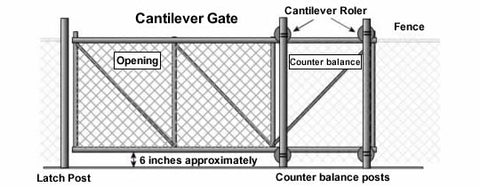

There are many types of slide gates, one of the most unique is the cantilever slide gate. Cantilever gates are unique because they don’t roll on the ground. The gate is supported by a series of trucks (rollers) attached to two support posts on one side of the opening. The distance between these posts is usually equal to half the length of the gate opening. There are two important factors you should take into consideration when selecting your cantilever slide gate:

- Elevations– To install a cantilever slide gate, the area must be level. This is both for the most recent standards and codes and for practical safety reasons. If a cantilever gate isn’t installed leveled, it will roll downhill. Inspect the elevations of the finished grade underneath the entire travel of the gate from the nose of the gate in the closed position, to the back of the tail in the full-open position. The highest elevation will be your benchmark. The gate should be set at least two inches above this elevation. If the highest elevation of the gate is at the tail section and the elevation slopes down through the opening, this will cause a considerable gap under the gate at the opening.

- Gate Storage– Cantilever slide gates are approximately 50% larger than the gate opening. So, a 20’ opening would require a 30’ overall gate leaf. This excess portion of gate is called the “counter balance” and is considered to be the tail of the gate. Determine if your site has enough room to accommodate the opening and storage of the gate by inspecting and evaluating your site location.

Cantilever Gate Infill Type

After site evaluation and inspection, and determining if the area is level and can accommodate your gate, you should now consider the various performance and design factors of selecting a cantilever sliding gate. The first factor to consider is the type of infill, which will dictate the design and materials of the gate. Though these categories are very broad, selecting one will better help designers and contractors understand your vision. America’s Gate Company supplies CAD drawings and specifications for any of the styles of infill mentioned below. If you have questions or need some help following reading this article, please reach out to the America’s Gate Company team.

Ornamental Cantilever Gate

An ornamental cantilever gate will incorporate vertical pickets into the gate frame at the opening. The size of these pickets is generally ¾” to 1”. In accordance with ASTM A2200 and UL325, the pickets should be spaced so the gap is no greater than 2 ¼” throughout the entire length of the gate, in case it ever would be automated. The bottom rail of the gate should be flush, with no pickets sticking out. Pickets may extend above the top rail of the gate and be adorned with an ornate cap. Ornamental cantilever gates may also include other adornments throughout the infill area of the gate.

Decorative Cantilever Gate

The difference between a regular ornamental cantilever gate and a decorative ornamental cantilever gate is that decorative gates include an infill material that is unique and aesthetically appealing, but not of a picket design. The gate infill material may include the use of a solid slating, louvers, perforated metal, etc. To be an automated gate, decorative cantilever sliding gates also require gaps no larger than 2 ¼” throughout the gate. Another factor that makes decorative cantilever gates separate from ornamental slide gates is because the mix of infill materials typically causes both wind load and weight concerns for the gate. However, if either of these situations are a potential concern or hazard for your project, ornamental cantilever slide gates with picket infill do not suffer wind and weight distress and may be a better option for your project.

Chain Link Cantilever Gate

The most common and widely used type of cantilever slide gate is the chain link cantilever gate. Much like the ornamental and decorative cantilever slide gates, chain link cantilever gate should not have gaps greater than 2 ¼” throughout. To accomplish this, chain link fabric can be extended throughout the entire length of the gate. There is no weight or wind concern with a chain link cantilever gates as the chain link fabric is 98% open.

High Security Cantilever Gate

Some project site require added security to an already secure cantilever gate. High security cantilever slide gates include solid surface infill or tight wire-mesh materials which makes them unable to climb. These gates are also kept tight to the ground to keep intruders from going underneath and are generally very tall to keep intruders from going over. These features help to keep unauthorized personnel out and keep your property secure. Some concerns for high security cantilever slide gates are their wind loading and weight. The solid surfacing or tight non-climbable wire mesh is much heavier and more dense than standard chain link fabric. Designers should pay special attention to site elevations specific to the path of these cantilever gates. Elevation changes in the overall travel of the gate may result in gaps under the gate when installed level.

Gate Opening

Once you have selected the overall use and material of the gate, it is now time to consider performance factors and structural elements that are directly affected by this design. The opening width of the gate is the single most important detail of the overall gate design. The opening width of the gate, along with the selected infill materials, will greatly influence the type of structural gate frame needed to support the gate for both weight and wind loading.

Single Track Gates

To use a single track on a gate, the gate opening must be less than 27’ with standard chain link or ornamental picket infill. Aluminum cantilever slide gates with an opening of 27’ or less incorporate a single track into the aluminum structure of the gate, and are the most economical cantilever option. The track is at the top of the gate and offset to one side to form one of the following conditions:

- Inline cantilever gates place the track to the face of the gate. The gate support posts that support the trucks are set in the fence line with the gate behind the fence line.

- Offset cantilever gates place the track to the backside of the gate. This puts the cantilever gate support posts behind the gate. The support posts are both offset and independent of the fence line.

- Single track cantilever gates are typically used with openings less than 27’ and with standard chain link infill materials.

Double Track Gates

Chain link and ornamental cantilever gates with openings of 27’ or more, or decorative gates with solid or semi-solid infill are typically double track gates. They incorporate a double track into the aluminum structure of the gate where there is one track at the top of each side of the gate.

This application requires four gate support posts with two on each side to support the rollers. In addition to having two tracks, roller and support posts combine to support the weight of the gate, as a double track cantilever gate has a much wider horizontal structural profile. This wider profile provides greater support for wind loading.

While a standard single track cantilever gate has a horizontal profile of approximately of 5”, a double track cantilever gate has a horizontal profile of approximately double that of a single track cantilever gate.

Modified Double Track Gates

A standard double track gate can be modified for larger openings or larger decorative gates with solid or semi-solid infill. The horizontal profile of the gate is widened by implementing structural profiles into the upper track assembly to spread the tracks apart, and by providing a wider lower guide track.

The standard width for a double track cantilever gate is approximately 10” wide at the upper track assembly; a modified double track gate may range from 12” – 16” at the upper track assembly. As for the lower guide track, it is typically 5” wide for double track gates and may be widened up to 8”. The purpose of these wider upper and lower assemblies of the gate is to provide greater structural support for wind loading on the cantilever gate.

Modified double track cantilever gates are not standard and these modifications should be engineered and implemented by the gate fabricator accordingly based on the design of the gate.

Box Cantilever Gates

The design of box framed cantilever gates is rooted in the simple design elements of a standard truss system. A box cantilever gate is basically two identical cantilever gates, spaced approximately 24” apart with a series of truss members placed between the two gate panels to form a pattern of diagonal trusses.

A box cantilever gate uses four truss systems like a steel building ceiling truss to create a very rigid overall framework under a heavy load and/or high winds. Box framed cantilever gates are typically reserved for very large openings in excess of 50’ or solid materials placed across the gate opening.

Gate Height

When it comes to the structural design, the gate height may not be as important as the overall gate opening, but it does have a significant impact on certain design criteria like wind load. The taller the gate, the more the wind load is going to bear on the face of the gate. When selecting your cantilever gate size, here’s the performance criteria you need to consider:

Infill Materials

Using solid infill materials on the face of gates taller than 6’ may require re-evaluating the gate frame design. Regardless if it has a single or double track, the impacts of high winds on a solid surface gate face may be destructive. No matter the gate’s opening width, a box cantilever gate should be considered if high winds are a factor in your project’s location.

A perforated sheet, welded wire mesh or allowing an opening in the face of the gate can be considered to reduce wind loading by relieving pressure. An example of this would be a decorative cut-out from weather sheet metal (e.g. mountain scene, trees, etc.) where an opening is left for pressure release.

Gate Support Posts and Footings

While your cantilever gate post selection and footing size should be appropriate to the overall weight and size of your gate, it is important to keep in mind that the taller your gate, the greater the load you are placing on these posts. This is because you are allowing any wind load to have more leverage with taller gate posts.

8’ tall or less is a standard cantilever gate height. These standard cantilever gates use 4” O.D. ASTM 1043 gate posts regardless of the overall length of the gate. This is because the majority of the load being placed on the gate posts is not a cantilevered load but a load that is pulling and pushing, stressing the tensile strength of the posts which is in the tens of thousands of pounds. Taller gates, 10’ or taller, may use 6-5/8″ O.D. schedule 40 posts to accommodate both the stress on the tensile strength and cantilevered load placed on the gate.

Cantilever Gate Hardware

Gate hardware for cantilever gates is fairly standard regardless of the weight, length and width of the gate. The selection of hardware is more specific if the gate is an enclosed aluminum track gate or a steel tubular gate with external rollers. Once the gate begins to exceed 2,000 pounds, you should consider using non-standard, heavy-duty gate hardware. Specifically, the rollers or trucks that support the weight of the gate while allowing it to roll freely. Your gate designer should appropriately match the gate hardware, trucks, rollers, and guides, to the type, size and weight of the gate.

Gate Weight

Cantilever gates rarely exceed 2,000 pounds. Non-typical, heavier gates are the result of openings longer than 30’ or heavy solid infill materials in the opening section of the gate used for decorative reasons. To accommodate these non-typical heavy gates, consideration should be given to the following:

Single or Double Tracks

Aluminum enclosed track gates offer both single and double track options with one track on each side of the gate. This double track design a superior choice for both longer and heavier gates as it spreads the load of the gate on four truck assemblies rather than two like on a standard single-track design. Openings exceeding 27′ in width usually require double track gates.

Gate Truss Design

Cantilever gates use a standard diagonal truss design throughout the length of the gate to support the cantilevered load of the gate. Building and bridge truss designs are very similar as the diagonal members are placed in-between vertical members.

On the top and bottom, there are continuous horizontal support tracks where the vertical members connect. This pattern of horizontal, vertical and diagonal supports creates a series of connected squares. The diagonal members prevent the squares from being pulled out-of-square by connecting opposite corners together. The only way the square(s) can be pulled out-of-plumb is for the diagonal member to be compressed or stretched.

This is where the tensile strength of metals comes into play. The tensile strength of most respective metals is in the tens of thousands, meaning it would take thousands of pounds to pull the diagonal truss apart, which is how a typical truss gets its structural strength.

If the diagonal members were removed from a gate’s framework, the squares would quickly bow under gravity. This is significant considering the cantilevered load for most respective metals is in the hundreds of pounds.

Cantilever Strength and Support

To support longer and heavier gates, a cantilever gate’s truss design can be improved. Most cantilever gate designs use a standard principle: The length of the gate’s vertical should be greater than the spacing of each vertical support. For example, if the vertical support is 72” tall, the vertical supports should not be spaced more than 72” apart from one another. Regardless of gate height, most cantilever gate designs do not exceed 72” spacing for vertical supports.

To improve the cantilever gate’s ability to support longer and heavier gate frames, the vertical supports can be moved closer together, forming more of a rectangle with the long side vertical versus a square. This adjustment will shift the stress on the diagonal truss from a cantilevered load where the diagonal truss will simply bend to relying almost entirely on the tensile strength.

Weight and Gate Hardware

Most of the hardware for cantilever gates—enclosed aluminum track gates and steel tubular external roller gates—are designed to safely support gates up to 2,000 pounds for continuous duty. Cantilever gate hardware for gates in excess of 2,000 pounds is considered non-typical and is not readily available.

Gate designers should be aware that most heavy-duty gate uses either a ground mounted truck assembly or an overhead trolley system. Both of these designs will cause significant re-design of a standard cantilever gate.

Resist the temptation to simply add more rollers and gate support posts in an effort to support larger cantilever gate openings. Cantilever gates are designed to allow the loading of the cantilevered section of the gate to occur evenly between two fixed points: the respective trucks and gate support posts. This spreads the load over a wide area. Placing intermediate additional support posts and rollers may cause the load to be more concentrated on a smaller area, thus placing more resistance against the rollers and potentially causing the gate frame to fail.

Cantilever Gate Type

-

Steel Cantilever Gates– Use round tubular profiles in the design of the gate.

- The top and bottom horizontal members are a 2 ½” O.D. tube that runs the length of the gate. This tube serves both as a structural support and as the gates top and bottom tracks. The rollers run on the outside of these tracks.

- In-between the vertical members are the diagonal supports. On steel cantilever gates, these are typically 1 5/8” O.D. tubing, however, cable may be substituted.

- The vertical gate members are 2” O.D. tube that are spaced no greater than 72” apart.

-

Aluminum Cantilever Gates– Use extruded aluminum square and rectangular profiles in the design of the gate.

- In-between the vertical members are the diagonal supports that can be either a 2” square aluminum or cable system.

- The top horizontal member is a custom extruded track and structural member(s) combination. The track is approximately 2 ½” wide by 2 ¾” tall. The trucks (or rollers) run inside the track. The trucks are supported from the bottom of the track and not hung from the top. This prevents water and debris from settling in the track.

- The vertical gate members are 2” x 2” spaced no greater than 72” apart.

- The bottom horizontal member is a 2” x 2” square (or 5” x 2” rectangle for larger gate openings). Not only does this member provide structural support for the gate but it also serves as the bottom guide.

Steel vs Aluminum

If you’re thinking about long-term upkeep of your cantilever gate, consider steel cantilever gates as they are more economical and often easier to repair opposed to aluminum. The rollers and gate hardware are also very heavy-duty. However, aluminum cantilever gates—the more expensive option—offer more design options:

- Aluminum cantilever gates are an excellent choice with larger openings as the overall width of the upper and lower horizontal members may be easily extended without interfering with the track design. You can simply add additional structural supports or add a double track to the gate design.

- Box cantilever gates are almost exclusively manufactured from aluminum. The square profiles make it easy to join with other profiles creating a series of trusses, whereas a steel tubular design requires a considerable amount of coping. Most important, aluminum is stronger than steel pound for pound. This is important when the weight of the gate is what you are trying to support with the design.

- With the enclosed track system and square profiles, aluminum track cantilever gates are the best choice for ornamental and decorative gate designs. The square pickets may be placed between the top and bottom members or mounted on the face. The track may be positioned on the inside of the facility thus hiding it and the hardware from the outside, providing curb appeal.

Automation

If you are looking to make your gate automated, both aluminum and steel are excellent choices for automated gates. Aluminum cantilever gates will provide for more consistent travel in the overall travel of the gate as the enclosed track and truck system has tighter tolerances. Aluminum gates are lighter. If you have a very large opening or a very heavy gate by design, you may want to consider an aluminum design as it may require a smaller gate operator or place less stress on the gate operator. With openings under 27’ and typical chain link infill, a steel cantilever gate is an excellent and economical choice.